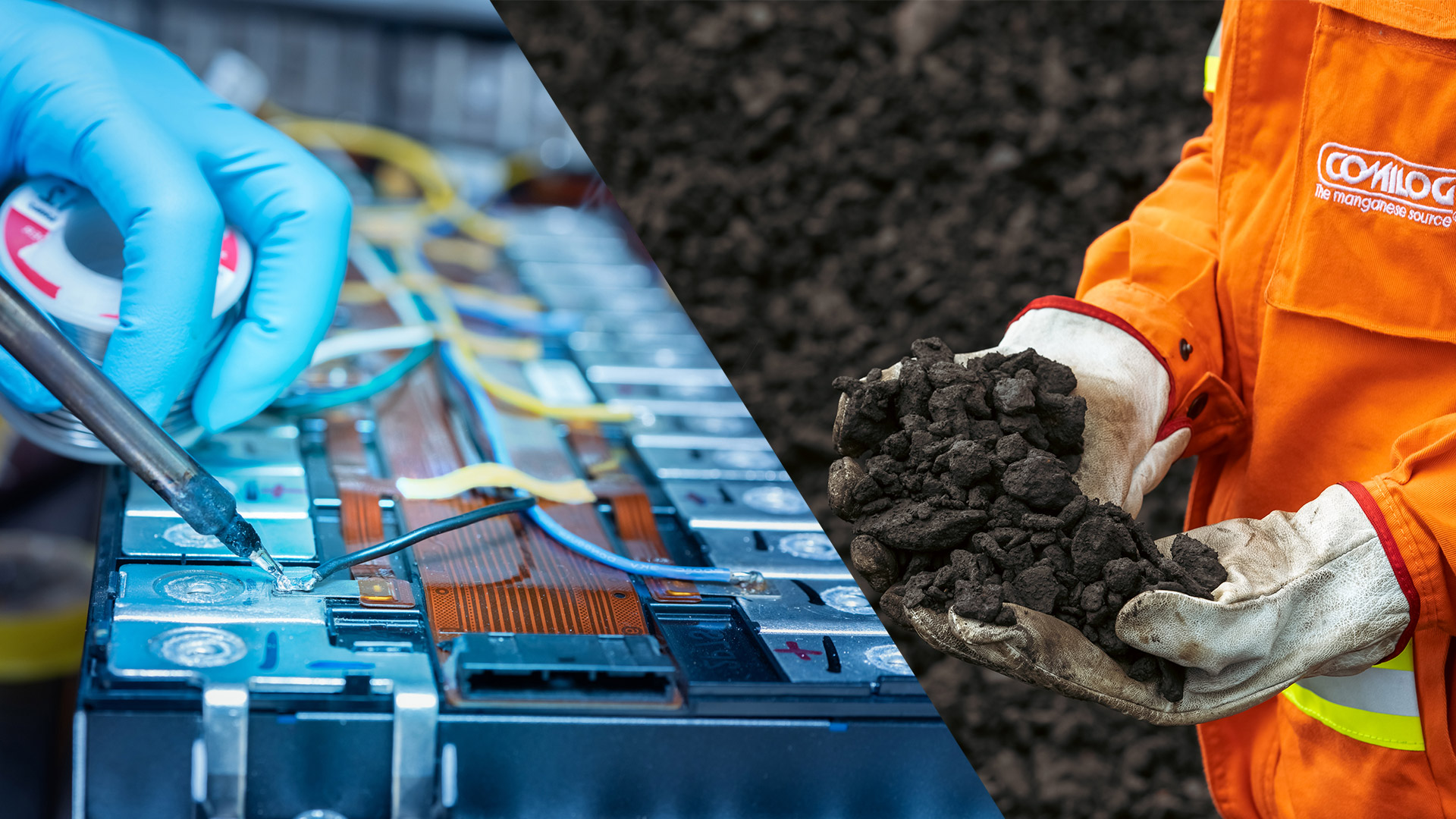

The star of the moment is lithium, the key ingredient in lithium-ion batteries for electric vehicles. But did you know that manganese, which is mainly used to make steel, is also needed to manufacture this type of battery?

Within the large family of lithium batteries, there are several sub-categories, such as LFP batteries (Lithium, Iron, Phosphate) or NMC batteries (Nickel, Manganese, Cobalt). Although the latter contain only small amounts of manganese, it is essential to the manufacture of the cathodes through which the current flows. And as well as being highly resistant, NMC batteries also have the advantage of being lighter and faster to recharge than LFP batteries.

Where does this manganese come from? Today, most manganese is produced in China, which is why it is important to secure supplies from other sources. Eramet’s product portfolio includes all the elements needed to manufacture batteries and, more generally, for the energy transition: manganese via Comilog and Setrag in Gabon; lithium with the Centenario mine in Argentina; and nickel at Weda Bay in Indonesia.

“There is a renewed interest in manganese, and our ore is particularly appreciated for its quality and the CSR commitments associated with its production,” says Thomas Dugravot, Senior Sales Manager Manganese BU. “There is a future in this sector. We are receiving requests from numerous automotive manufacturers such as Renault and Tesla, who are looking to secure their supplies.”

Speaking of the future, in December 2023 Eramet signed a commercial agreement with Vibrantz, a US company, a US company specializing in chemicals for lithium-ion batteries. Under the agreement, Eramet will supply manganese ore to Vibrantz over a 10-year period, to fuel the production of manganese sulfate, a key ingredient for battery cathodes.

Both partners are also keen to contribute to the development of a responsible industry. For Eramet, this commitment is reflected in the IRMA certification audit planned for all its sites by 2026.