Zircon, a fake diamond? Yes, but it’s much more than that! Where does it come from? What is it used for? At Eramet, TiZir is the specialist in zirconium silicate.

Although zircon was identified for the first time in 1783, excavations indicate that its discovery goes back even further than that, with references to zircon appearing in Hindu and Judeo-Christian mythology.

Zircon – or zirconium silicate – is a “refractory” foundry sand, which means it resists very high temperatures and only melts at 2,550°C! At Eramet, TiZir is the specialist of zircon and mineral sands. This Eramet’s subsidiary is the world’s 4th largest producer of premium-grade or standard-grade zircon. It has two sites: Grande Côte Opérations (GCO) in Senegal, which extracts mineral sands, and TiZir Titanium & Iron – “TTI” – in Norway, which develops Senegalese ilmenite.

How is zircon extracted?

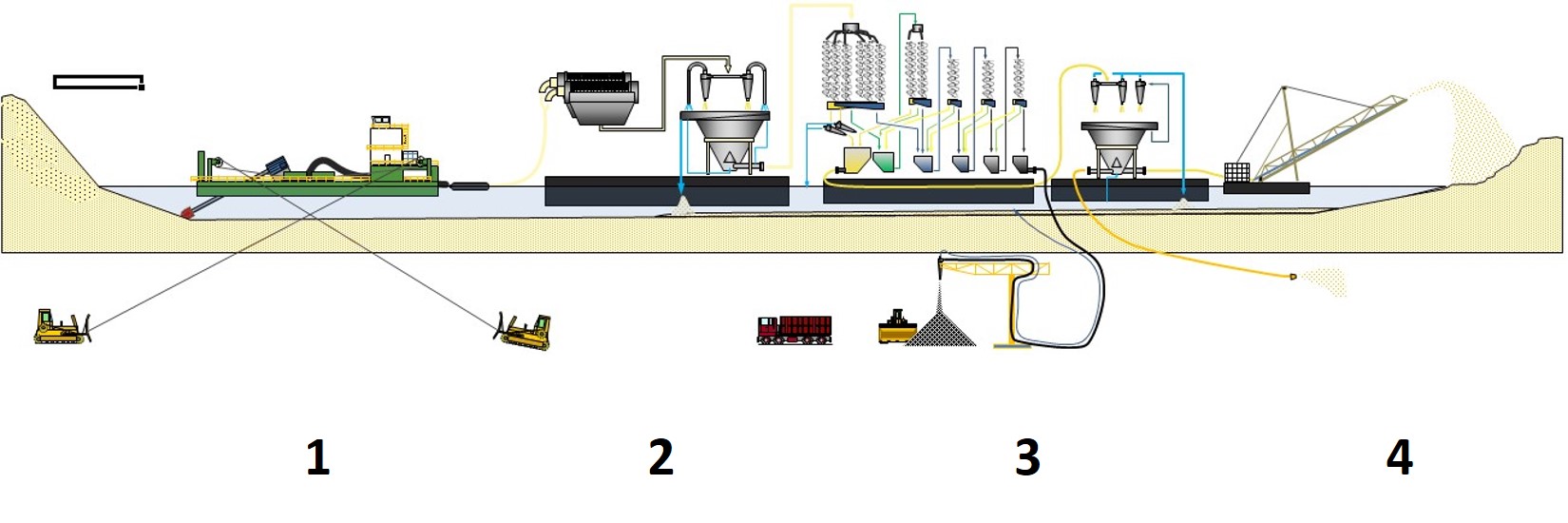

On the Atlantic coast, near Diogo, in northern Dakar, GCO operates a concession along a 100-kilometer stretch of dunes. A dredge floating in a shallow-water basin pumps up to 7,000 T of matter per hour. This matter comprises 1 to 2% of mineral sands – ilmenite, leucoxene, rutile, and zircon – and the rest is quartz sand. The extracted sands are then directly transferred to a “wet” concentration plan, located right behind the dredge where they are washed and separated according to their different densities. Quartz sand – the lightest – isn’t used by GCO and is then rejected to the back of the pond, naturally mixing in with the landscape.

- The dredge pumps the sand

- The wet concentration plant washes the sands

- The mineral sands are separated from “ordinary” sand

- The “ordinary” sand is rejected into the dunes

The usable sands are transferred to the separation plant where the four types of high-content sands — including zircon — are separated. Different separation methods are used, such as magnetic separation or electrostatic separation. Zircon, still in its sand form, is then packed in containers, either in bulk or in big bags; railed to the Port of Dakar by train; and then shipped to TiZir’s clients all around the world, mainly to industrial and ceramics-related companies like Imerys and Saint-Gobain.

What is zircon used for?

Known for its hardness, as well as its whitening and opacifying properties, milled zircon can mostly be found in frits and glazes, to be applied in ceramics – tiles or sanitary wear, for example. It is also known for its capacity to resist very high temperatures – remember, we told you earlier that it is “refractory” – and is often used in the industry to create moulds and slurry’s used to cast parts. Zircon sand is used as well in the production of fused zirconia, which is being used in pigments (for ceramics), automotive (used in brake pads) etc.

But zircon is also present in our daily lives: its anti-abrasive properties and its diamond-like shine make it a popular material in jewelry, where it can be found as zirconium dioxyde. It can even be found in dental prostheses although the quantities going into these applications are limited.